🔎

What the Pitti Filati S/S 2025 presented as trends that fit into a general context marked by the search for security and real values; less concept and more substance, with an invitation to live time at another speed. They are developed in 3 color themes that are inspired by thirty of the most striking places on the planet, divided into three groups by special affinities and color suggestions.The interpretation of yarns through the study of jacquard cloths and knitted stitch work.

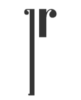

FLUID

A temperature range from cold to hot. Fluidity allows for smoothness and harmony.

TACTILE

Vibrant. Tactility allows you to be understood and perceived

CONCRETE

Sophisticated and mineral. Concreteness allows you to be real and effective in terms of expression and action

🔎

Another testimony to the interweaving effect of threads (Filmar stand). Homage to cotton, the raw material from which all the vibrant colors of the threads come to life. The work is made up of 1200 nails and over 180 km of yarn, creating a suggestive and exciting visual intertwining. Details of the panel created at the Filmar Stand. Author Martin Lucchini

Points from the Lineapiù stand at Pitti Filati. Always interesting…

Il colore per funzionare deve convincere 👀!

I like to feel inspired by multiple colors. As a child, when I picked up the colored pencil case I was attracted to rearranging the colors in chromatic gradation, finding the right order by trying and trying again. Doubt arose with 3 colors, to be placed at the beginning or at the end: white, gray, black and maybe even brown. But every color speaks even if there you want to ignore ✨

💡of how simple, lightweight plaids can be used differently, useful both at home and on the go, to take with you. They are warm and functional-a little convenience in more situations. You can choose to make them in carded merino wool or cotton-cashmere, in the proposal of the 3 geometric patterns inlaid with 7 colors, in the size of cm 160 x 190. An accessory: not a simple need but a desire…

Hints of material fibers to learn a little more about the terminology in use, beginning with those of natural origin derived from mineral animal plants (the oldest) and synthetic through chemical processes (early 900′). All are thin, flexible, elastic, strong structures, and by spinning come together to create the fabric.

The length, diameter and shine represent the morphological characteristics of the yarn and determine the 4 large categories: the vegetable, animal, artificial and synthetic fibres.

Plant fibers are obtained from the cellulose of plants: from seeds, for cotton and Kapok (fruit of a tree in the rain areas of South America resembling cotton but lighter); from stem, such as lin, hemp, hair and the ramiè; from the ribbing of the leaf, such as the rafia and sisal (Central American sisal agave) with a coarse and rough appearance, used to produce carpets and cordage

I clarify the easily confusing difference that exists between artificial and synthetic fibres. They are obviously not natural but they have important differences.

Artificial fibers are obtained from naturally occurring substances of cellulosic, alginic (organic compound derived from algae and used as a gelling substance) protein origin. They are pure or regenerated cellulose fibers mixed with chemicals. Numerous varieties are derived from: milk, pineapple, coconut water, cactus, beech and eucalyptus trees, citrus, corn, grape marc and fruit.

The synthetic fibers are derived from the chemical synthesis of petroleum or compressed petroleum gas and are divided into groups depending on their manufacturing process.

All wools that are not very common or come from valuable breeds of animals are defined as “special”.

A quick overview of animal fibers

CASHMERE: it is obtained from the chinstrap combing from the goats of Kashmir, Tibet and Mongolia. These sheep have long, bristly hair on the surface, with very fine, soft down on the bottom.CASHMERE: it is obtained from the chinstrap combing from the goats of Kashmir, Tibet and Mongolia. These sheep have long, bristly hair on the surface, with very fine, soft down on the bottom.

CAMEL WOOL: It is obtained from the African dromedary of Egypt and the Sahara or the Asian camel, China and Mongolia. It is harvested when it falls naturally from the animal’s belly or as a result of combing.

ALPACA WOOL: It is obtained by shearing from camelids in the Andes, when the hair reaches 20-25 cm in spring. The keratin in alpaca wool is highly prized and is also used in the cosmetics industry.

ANGORA: it is collected by combing from the goat and the Angora rabbit, both of which have long, silky and very shiny hair. It is always used together with other fibres.

VIGOGNA (OR VICUNA): comes from the smallest of the camelids, which lives at an altitude of 4,000 meters in the highlands of Argentina, Bolivia, Chile, Ecuador and Peru. This animal produces only 250 g of hair every two years. Its fleece, nicknamed “fleece of the gods,” is 10-15 cm long and is the world’s most exclusive textile fiber. Shearing and processing of this wool still take place following ancient traditional methods. The fiber is left in its natural color, which ranges from white to golden brown.

MERINO WOOL: This is made from merino sheep, a sheep native to Spain but now found all over the world (Australia, New Zealand, Germany, Iceland,South America and Africa). The fiber of this fleece is very fine and allows for the processing of fabrics such as cool wool.

SHAHTOOSH: declared illegal and banned from all markets, it was obtained from the girth of the chiru, a Tibetan antelope at risk of extinction.

ANIMAL FIBERS

They consist of protein substances. The most common remains wool, obtained from animals such as sheep, rabbits and some types of llamas through the removal of hair. Wool harvested through shearing is called “shearing wool” and is distinguished from “tanning wool,” which is obtained from dead animals and is less elastic and soft, as well as inferior in quality. The operations following wool collection are spinning procedures: these are carding and combing.

CARDING

Carding means untangling textile fibers and cleaning them of any impurities. Carding is done using cardi, in manual processing, or carde, in mechanical processing. The fibers are thus made soft and ready for spinning.

THE COMBING

Combing is used to arrange the fibers in a parallel manner, removing the last impurities and fibers that are too short. It is carried out by processing the fiber mass in “combing machines.” The yarn is homogeneous and, if obtained from long fibers of the best quality (such as fine merino or crisscrossed wools), will be smooth, thin, compact and well finished.